BULLETINS

FLAMMABLE FABRICS

September 2, 2022

Amber Prince

DEFEND AGAINST ARSON

October 31, 2019

Govspec

FLAMMABLE PLASTICS

May 15, 2019

Amber Prince

Flammable Fabrics

Flammable Fabrics Act and Wearing Apparel Flammability

Flammability of wearing apparel was not regulated until the early 1950s with the introduction of the Flammable Fabrics Act which attempted to rule out dangerously flammable clothing. Administration of this new regulation was with the Department of Commerce. Enforcement of the regulation was assigned to the Federal Trade Commission (FTC).

At the time, the main concern was clothing made from fabrics having an extremely high surface finish such as flannels which could be easily ignited by a small flame and burn rather rapidly.

A group of industry leaders (fabric suppliers, garment suppliers, retailers, and others in the trade) were brought together to develop a test which would classify materials as to their degree of flammability.

The actual test procedure was published under the designation CS 191-53; CS being “Commercial Standard”, 53 being 1953.

This commercial standard was incorporated as part of the Flammable Fabrics Act.

The main focus of CS 191-53 was to strike the fabric surface with a small flame with a rapid one second flame application. Potentially, fabrics with flannel, fleece, or similar raised fiber type surfaces could possibly ignite during the one second flame application.

Fabrics without raised surfaces (plain surface fabrics) usually do not ignite during the one second flame application. The exception could be lightweight fabrics usually weighing less than 2.6 ounces per square yard. With product liability as a concern, testing heavier fabrics should be considered.

If the fabric is ignited, the test measures the time it takes to burn a 5” section of the fabric.

The reported time for “Plain Surface Fabrics” is rather straight forward.

The reported time for “Raised Surface Fabrics” can be rather complicated as the test technician sometimes needs to determine the intensity of any surface burning as it relates to the burning of the base material. CS -191-53 provided guidance as to reporting times to determine the product classification. A similar test, CS 192-53, exists to measure the burning time of a 5” section of vinyl type materials. In this test, the flame is applied to the edge of the material.

It should be noted that CS 192-52 requires that the flame be held in position until ignition occurs.

The author is unable to explain why the textile test (CS 191-53) limits the flame application time to one second while the vinyl test (CS 191-53) does not specify a limit to the flame application time.

With regards to CS 191-53, the author can understand the rationale of surface flame application for “Raised Surface Fabrics”. He cannot understand why the flame is not applied to the edge of “Plain Surface Fabrics”.

At the time that CS 191-53 was developed, there was similar work undertaken by ASTM (American Society of Testing Materials) and NFPA (National Fire Protection Association).

The ASTM standard, ASTM D1230, is under active management by the association and is updated on a continual basis. The ASTM version pretty much parallels CS 191-53 (CFR 1610).

The NFPA version was discontinued in 1982, in other words NFPA decided not to manage and update the standard. In the author’s opinion, this remains a valid test method.

The NFPA version, NFPA 702, is significantly different from both the federal test and the ASTM test with regards to the point of flame application and flame application time.

In the NFPA test, the flame is applied to the edge of the plain surface material being tested. The application of the flame to raised surfaced materials stays with applying the flame to the surface rather than the edge of the material.

The most dramatic difference is that the NFPA 702 flame is held in contact with the material until ignition occurs as opposed to the one second flame application time of the federal test and the ASTM test.

Also of interest is international standard ISO 6941 that can be used to measure the flame progression of materials held in a vertical position using various flame application times.

In the late 1960s, the Department of Commerce was tasked to expand the Flammable Fabrics Act to identify products other than general wearing apparel.

Children’s sleepwear sizes 0 to 6X was one of the earlier products to come under the expanded Flammable Fabrics Act FF 3-71. Later sizes 7 to 14 were regulated by FF5-72.

The children’s sleepwear test differed dramatically from the one second surface flame impingement of CS 191-53. FF 3-71 and FF 5-72 call for a 1.5” flame to be applied to the bottom of edge of the sleepwear material for a period of 3 seconds.

FF 3 -71 and FF 5-72 went a step further and required not only testing of the fabric itself but also required testing of modifications to the fabric in garment construction. They require testing of the seams joining the fabric, laces, and other trims added to the fabric, screen prints, etc.

NOTE: Depending upon the size and fit of the garment, some children’s sleepwear garments remain under mandate of CS 191-53 (recodified – see below).

In the early 1970s, administration and enforcement of the Flammable Fabrics Act was transferred to the Consumer Product Safety Commission.

The tests were recodified as follows:

From: Department of Commerce

CS 191-53

CS 192-53

FF 3-71

FF 5-72

To: CFR (Title 16)

Part 1610

Part 1611

Part 1615

Part 1616

This summary is offered as a ready reference. The reader is referred to all the referenced documents to form their own opinion as to what the referenced documents legally mandate.

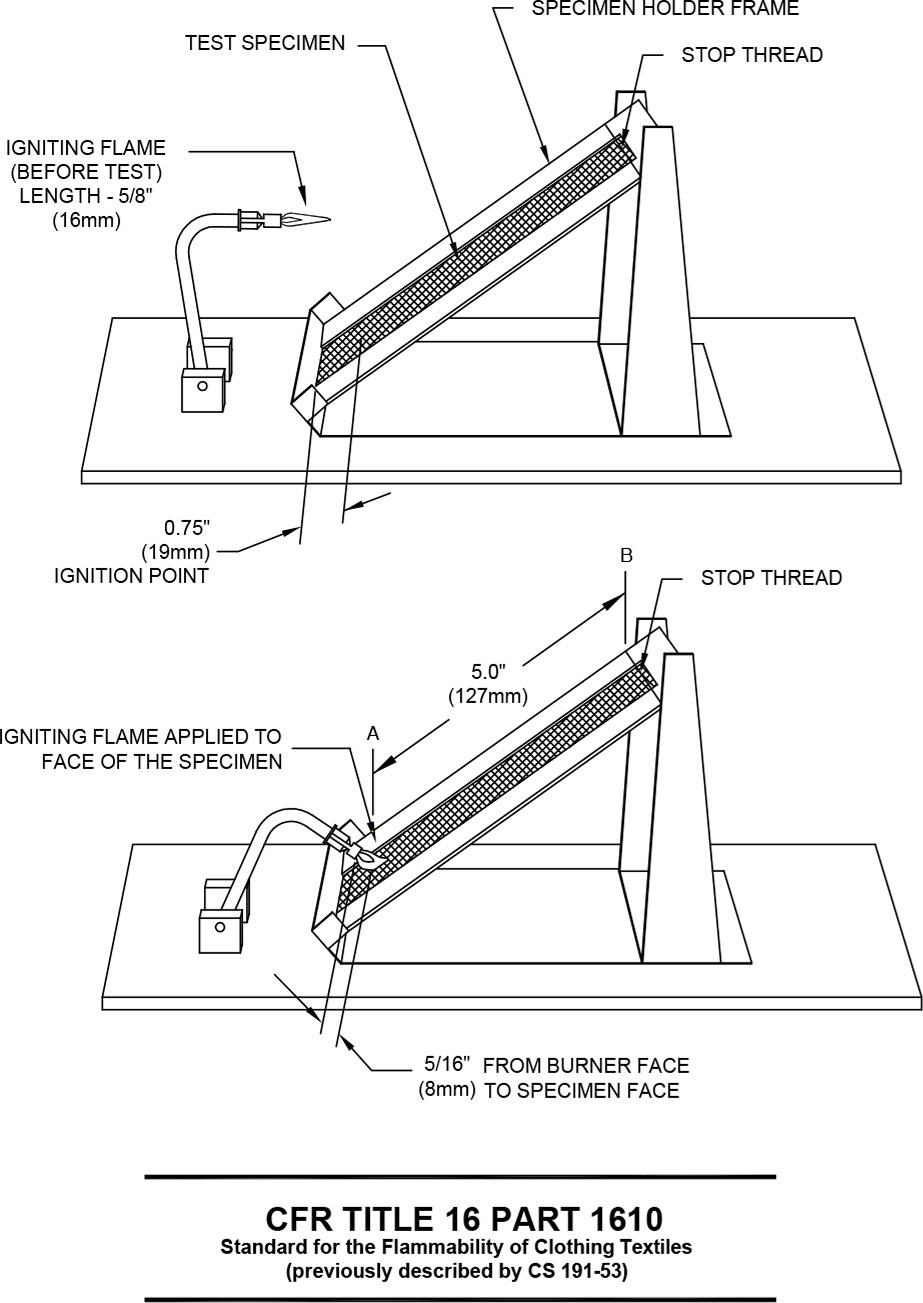

Part 1610 – Standard for the Flammability of Clothing Textiles

(Previously described by CS 191 – 53)

SCOPE/PURPOSE OF TEST:

Federal flammability standard for all fabrics used in general wearing apparel.

[Does not include certain children’s sleepwear items which are regulated by CFR Title 16 Part 1615 (FF 3-71) and CFR Title 16 Part 1616 (FF 5-74).]

BRIEF DESCRIPTION OF TEST:

The test material is held on three sides by a metal frame. The material is then placed into the tester and sits at a 45o angle. The surface of the test specimen is touched by a 5/8” (16 mm) long, pencil-thin flame for a period of 1 second. If the material is ignited, the testing machine automatically records the total time for a 5” (127 mm) strip of the material to be consumed.

CLASSIFICATION SCHEME (See Comments):

| Burning Time | ||

|---|---|---|

| Raised Surface Textile Fabrics | Plain Surface Textile Fabrics | |

| Class I: (Normal Flammability) | More than 7.0 seconds or NRBT | Minimum 3.5 seconds or NRBT |

| Class II: (Intermediate Flammability) | 4.0 to 7.0 seconds | Not applicable |

| Class III: (Rapid & Intense Burning) | Less than 4.0 to 7.0 seconds | Less than 3.5 seconds |

NRBT = No recordable burning time

ACCEPTANCE CRITERIA (See Comments):

| Burning Time | |

|---|---|

| Raised Surface Textile Fabrics | 4.0 seconds minimum average or NRBT |

| Plain Surface Textile Fabrics | 3.5 seconds minimum average or NRBT |

NRBT = No recordable burning time

Part 1610 – Standard for the Flammability of Clothing Textiles

(Previously described by CS 191 – 53)

COMMENTS:

Plain Surface Textile Fabrics

The report for plain surface materials is rather straight forward.

- In those instances where the material is ignited, there are usually two outcomes:

- The flame will progress to a thread that is spaced five inches from the point of flame impingement. Once the thread is severed, the machine will automatically display the number of seconds that had elapsed from the time of flame impingement. This value (number of seconds) should be entered onto the test report.

- In some instances, the material might burn and self-extinguish before the thread is severed. In this instance, there is no recordable burn time (NRBT). The entry on the test report should be IBE-NRBT

- If the material does not ignite, the report entry should be DNl-NRBT. The reader should review the classification scheme of CFR 1610 to form their own opinion as to entering test report information.

Raised Surface Textile Fabrics

Reporting for raised surface materials is much more complex due to the burning behavior of the raised surface materials. As a result, the author is unable to give the reader a simplistic narrative.

Much has to do with the intensity of the flame if the surface fibers are ignited and whether or not the supporting base fabric is ignited. Also, the area where ignition takes place affects the value to be reported.

The reader should review the classification scheme of CFR 1610 to form their opinion as to entering test report information.

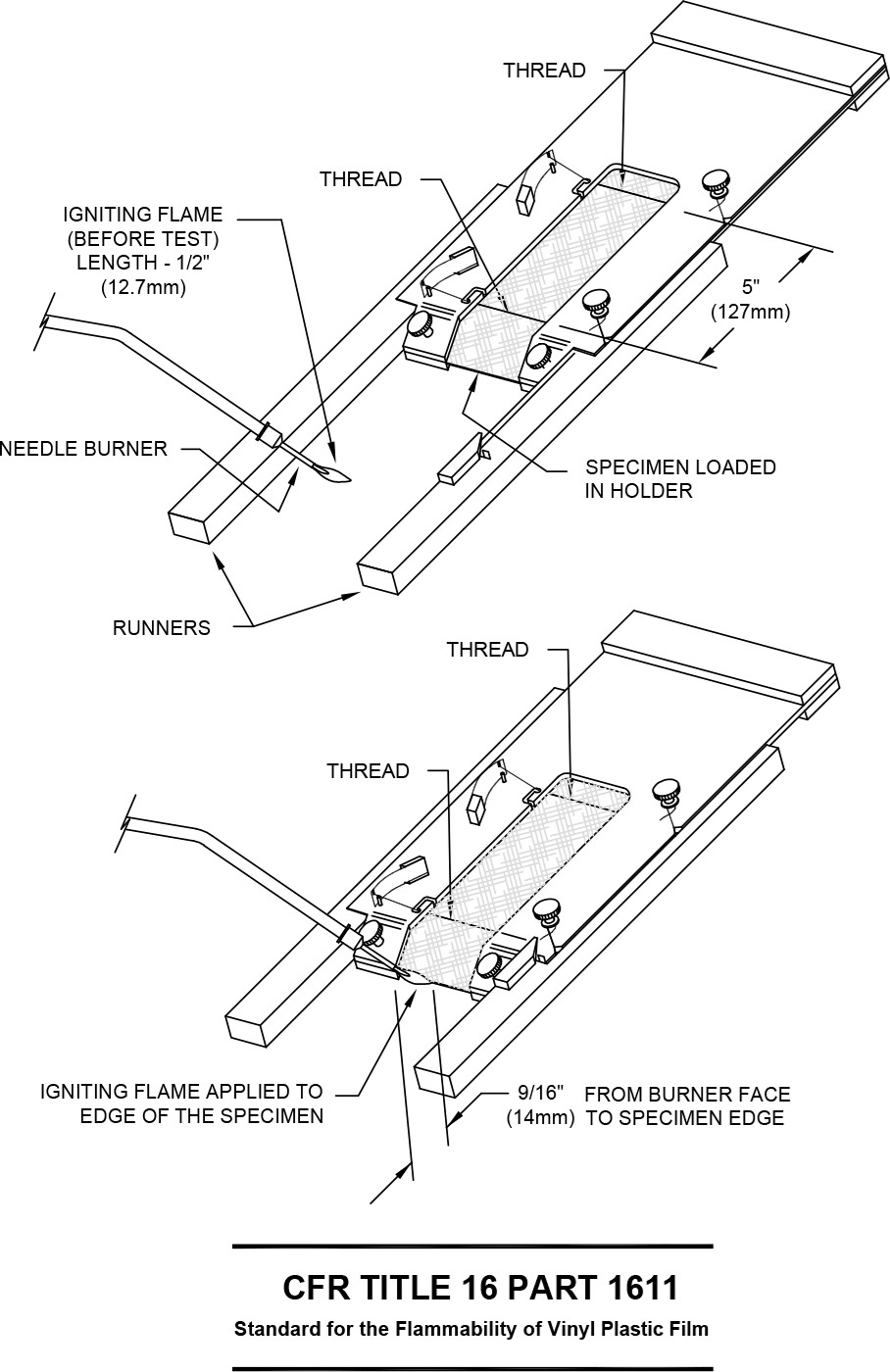

Part 1611 – Standard for the Flammability of Vinyl Plastic Film

(Previously Described by CS 192 – 53)

SCOPE/PURPOSE OF TEST:

Federal flammability standard for vinyl plastic films which are used in general wearing apparel. The standard lists the following materials that fall within the regulation: nonrigid, unsupported, vinyl plastic film, including transparent, translucent, and opaque material, whether plain, embossed, molded or otherwise treated.

BRIEF DESCRIPTION OF TEST:

The ignition source for this test is a stationary 1⁄2 pencil thin flame. The material to be tested is supported by a three-sided metal frame (specimen holder). On the upper surface of the metal frame (specimen holder) there are two sets of threads which are spaced at a distance of 5 inches from each other. Each thread is connected to a device which will activate a microswitch if the thread is severed.

The framed material is placed on a set of guide rails (runners). The guide rails are set at a 45-degree angle. The framed material rides down the guide rails until it comes to a stop so that the stationary igniting flame impinges on the exposed edge of the test material. CFR 1611 does not indicate how long the specimen is held in place to achieve ignition of the specimen. (Govspec suggests 20 seconds.)

If the specimen is ignited, there are two possibilities:

- Burning will sever the first thread and continue to burn through to the second thread. The tester will automatically record the time that was consumed in burning the 5-inch strip. This time value can be used to calculate a burn rate.

- Burning will self-extinguish before reaching the second thread.

BURN RATE CALCULATION:

| Formula: | Distance between threads Number of seconds shown on Burn Timer | = Burn Rate | |

| Examples: | 5.0″ 9 seconds | = 0.56″ per second | (PASSING RESULT) |

| 5.0″ 4 seconds | = 1.25″ per second | (FAILING RESULT) | |

FAILURE CRITERIA:

Burn rate exceeds 1.2″ per second*

* It should be noted that two groups of five specimens are tested. If in either set (group) there are less than two recorded burn times, CFR 1611 bases pass/fail on the outcome of the individual results. The system is too complex to summarize. The reader is referred to CFR 1611 to form their own conclusion.

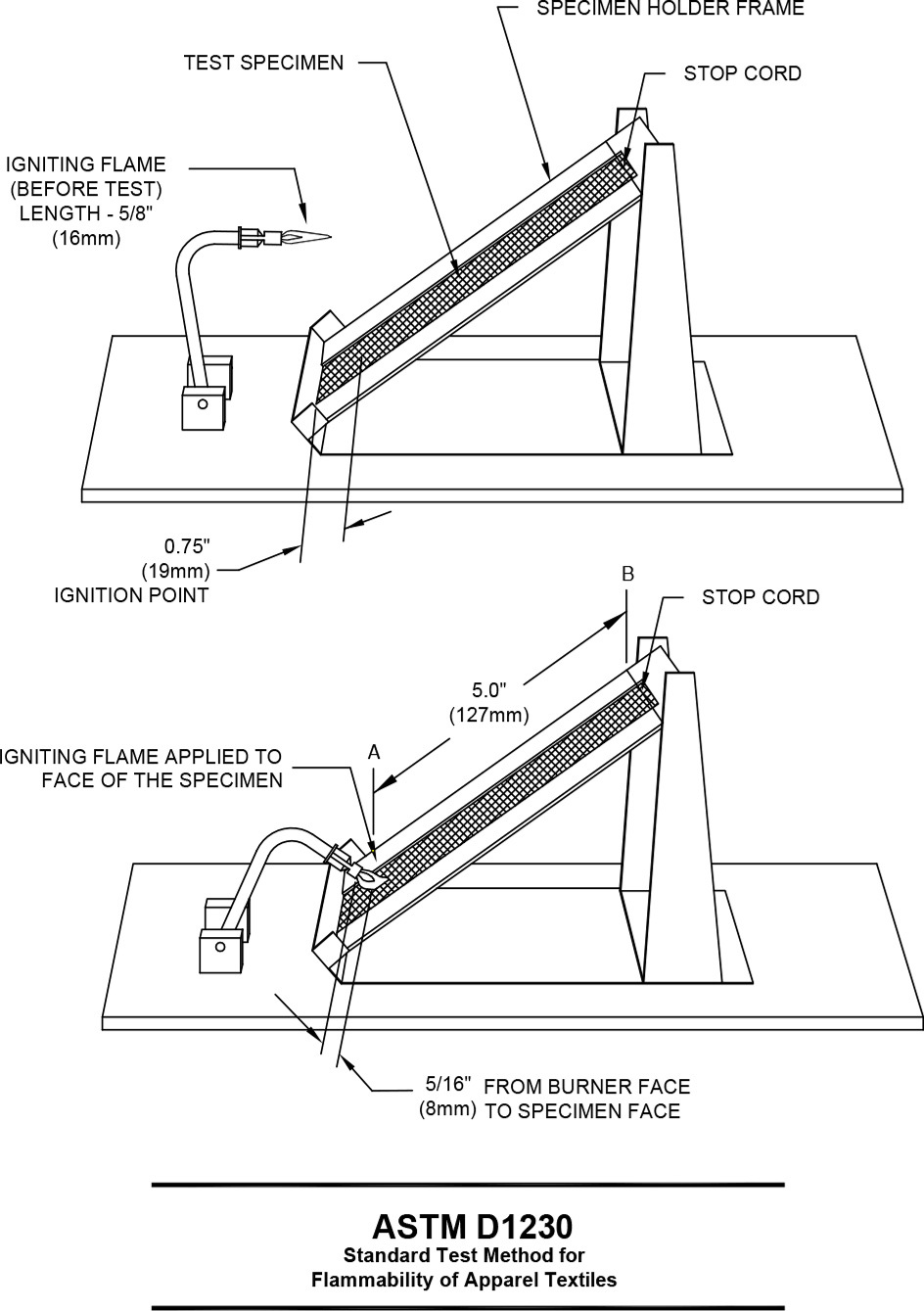

Standard Test Method for Flammability of Apparel Textiles

SCOPE/PURPOSE OF TEST:

This test method covers the evaluation of the flammability of textile fabrics as they reach the consumer for apparel items other than most children’s sleepwear.

BRIEF DESCRIPTION OF TEST:

The test material is held on three sides by a metal frame. The material is then placed into the tester and sits at a 45o angle. The surface of the test specimen is touched by a 5/8” (16 mm) long, pencil-thin flame for a period of 1 second. If the material is ignited, the testing machine automatically records the total time for a 5” (127 mm) strip of the material to be consumed.

CLASSIFICATION SCHEME (See Comments):

| Average Time of Flame Spread | ||

|---|---|---|

| Textiles That Do Not Have a Raised Fiber Surface | Textiles Having a Raised Fiber Surface | |

| Class I: | (a) Minimum 3.5 seconds or (b) No specimen ignites | (a) Minimum 7.0 seconds or (b) Less than 7.0 seconds with stipulations** or (c) No specimen ignites* |

| Class II: | Not applicable | 4.0 to 7.0 seconds with stipulations** |

| Class III: | Less than 3.5 seconds | Less than 4.0 seconds |

*ASTM D1230 doesn’t appear to take into consideration those textiles which may ignite and self-extinguish before severing the “stop thread” which is spaced 5’ from the point of flame impingement. if the “stop thread” is not severed, there cannot be a “recordable time of flame spread”

**See comments

CLASSES DEFINED:

Class I:

Textiles that are considered by the industry to be acceptable for general textile and apparel uses.

Class II:

These textiles are considered by the trade to have flammability characteristics for general textiles and apparel intermediate between Class I and Class III fabrics.

Class III:

These textiles are considered by the trade to be unsuitable for apparel.

Standard Test Method for Flammability of Apparel Textiles

COMMENTS:

Textiles That Do Not Have a Raised Fiber Surface

The report for these materials is rather straight forward.

- In those instances where the material is ignited, there are usually two outcomes:

- The flame will progress to a thread that is spaced 5” from the point of flame impingement. Once the thread is severed, the machine will automatically display the number of seconds that had elapsed from the time of flame impingement. This value (number of seconds) should be entered onto the test report.

- If the burning self-extinguishes before severing the stop cord, report: IBE.

- If the material does not ignite, report: DNI.

Textiles Having a Raised Fiber Surface

As per 1a above, the “Time of Flame Spread” for raised fiber surface materials is automatically recorded by the test instrument when the stop cord is severed by the burning test specimen; however, the determination to record the value shown for classification is rather complex based on the evaluation of what has occurred during the test.

In the author’s opinion, the recorded flame spread time will be valid for classification purposes if the specimen is totally consumed.

If the specimen is not totally consumed, ASTM D1230 instructs the user to evaluate the remaining portion of the test specimen to determine if the flame that was propagated during the test was of sufficient intensity to “ignite, char, or melt the base fabric.”

For this reason, the author has added “stipulations” in the “Classification Scheme.”

NOTE: The reader should review the classification scheme of ASTM D1230 to form their own opinion as to entering test report information.

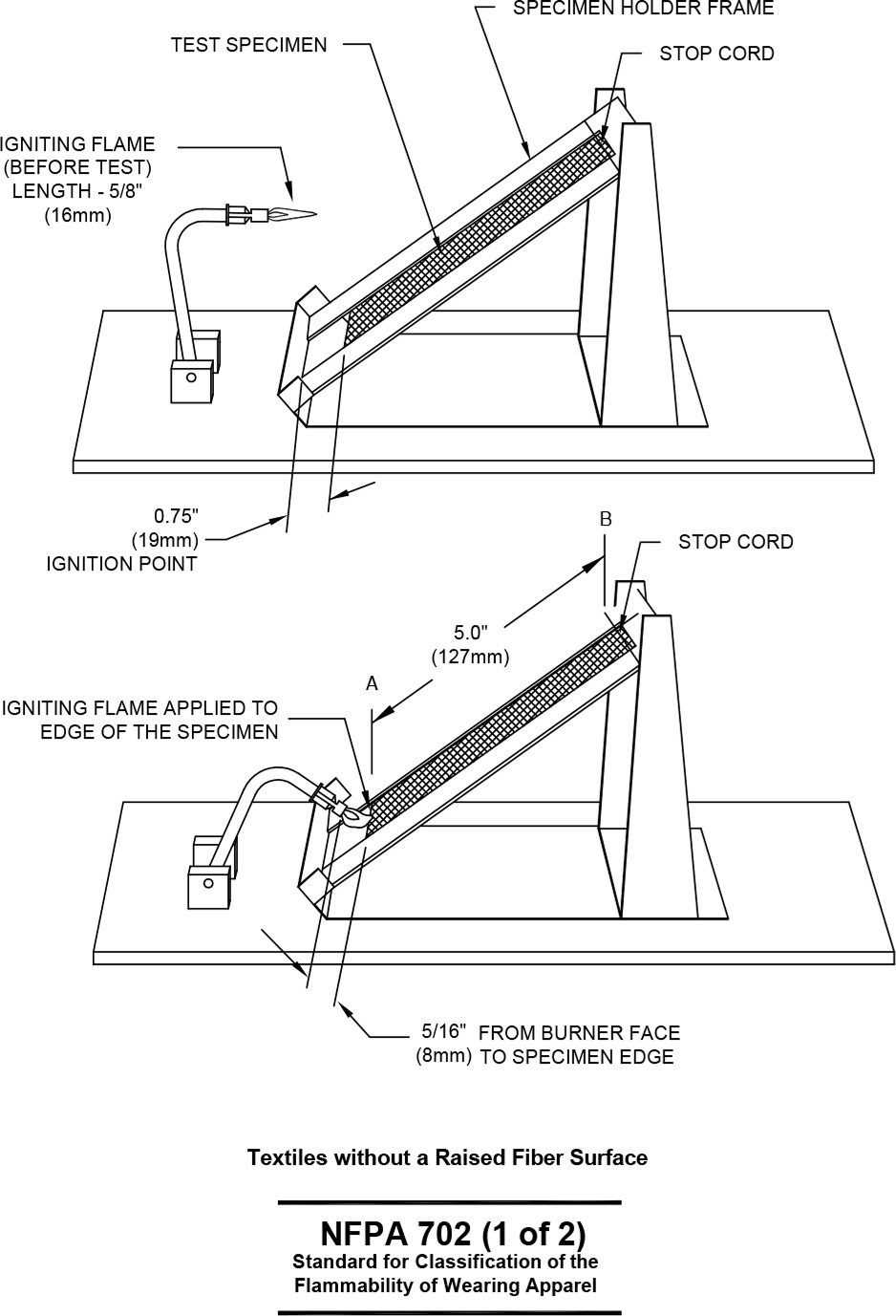

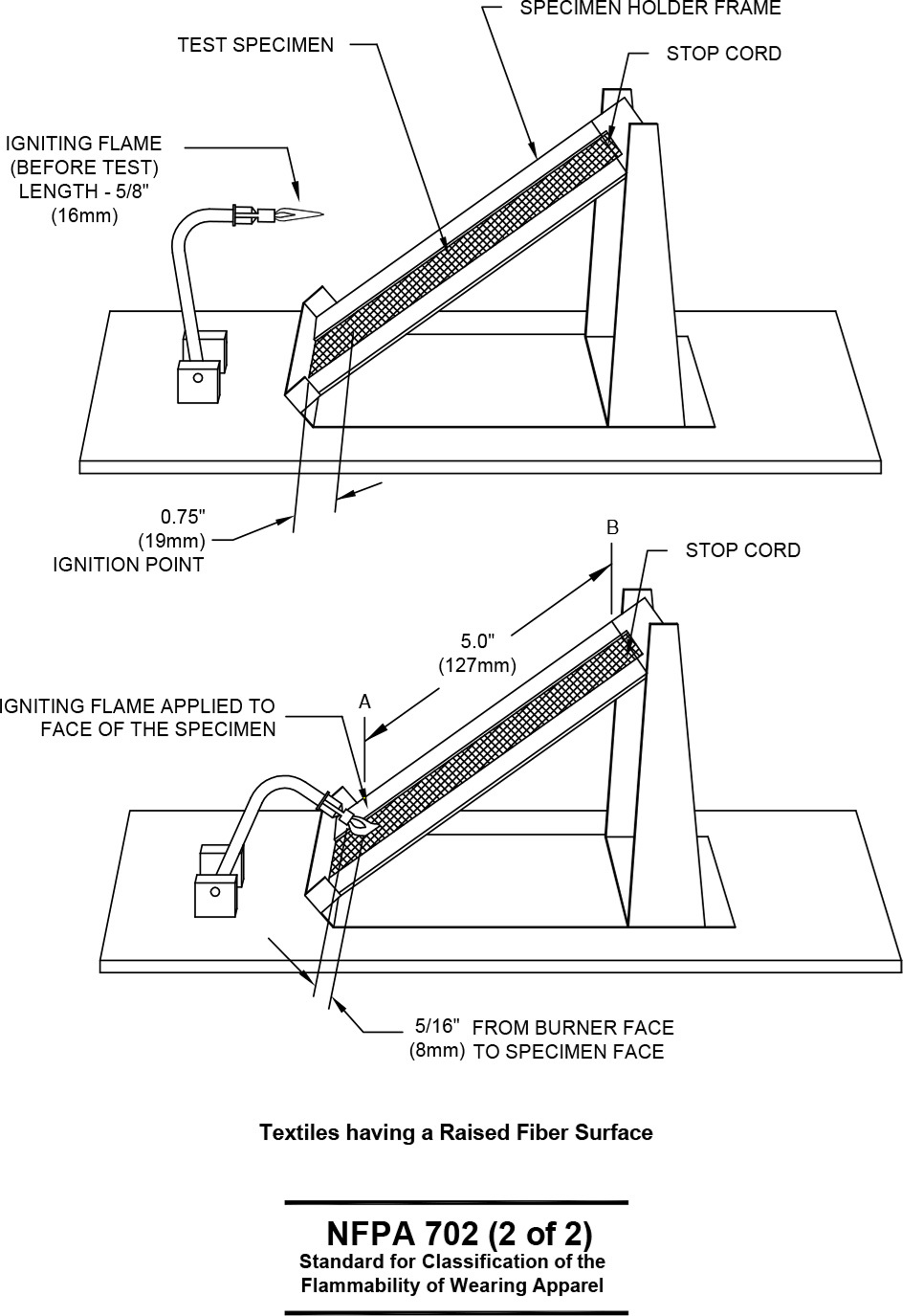

Standard for the Classification of the Flammability of Wearing Apparel

SCOPE/PURPOSE OF TEST:

To reduce danger of injury and loss of life by providing standard methods for testing and classifying the flammability of textile and other products for clothing use.

BRIEF DESCRIPTION OF TEST:

The test specimen is held in place by a metal frame. The positioning of the test specimen inside the metal frame is dependent on the surface quality of the specimen.

Textiles without a raised fiber surface: Positioned so that the igniting flame will contact the exposed edge of the test specimen.

Textiles having a raised fiber surface: Positioned so that the igniting flame will contact the specimen on its surface rather than the exposed edge.

The metal frame with the specimen is placed inside the tester and sits at a 45-degree angle. A pencil-thin 5/8” (16 mm) igniting flame is applied to the test specimen. The igniting flame is held in place until ignition occurs.

The standard requires the technician to report the total time from flame application to severance of the stop cord spaced 5” from the point of ignition (most testers sold since the 1970s are built to automatically record this time.)

The standard does recognize materials that ignite and self-extinguish before severing the stop cord. This is reported as IBE.

The standard does not recognize materials that do not ignite. The author recommends that DNI be reported.

CLASSIFICATION SCHEME:

Time of Flame Spread:

Class 1: 20 seconds minimum average

Class 2: 20 seconds minimum average

Class 3: 3 to 7 seconds average

Class 4: Less than 3 seconds average

Note: The automatic testers that are in the marketplace are accurate to 0.1 seconds. The classification scheme does not account for values that fall in between 19 – 20 seconds and 7 – 8 seconds.

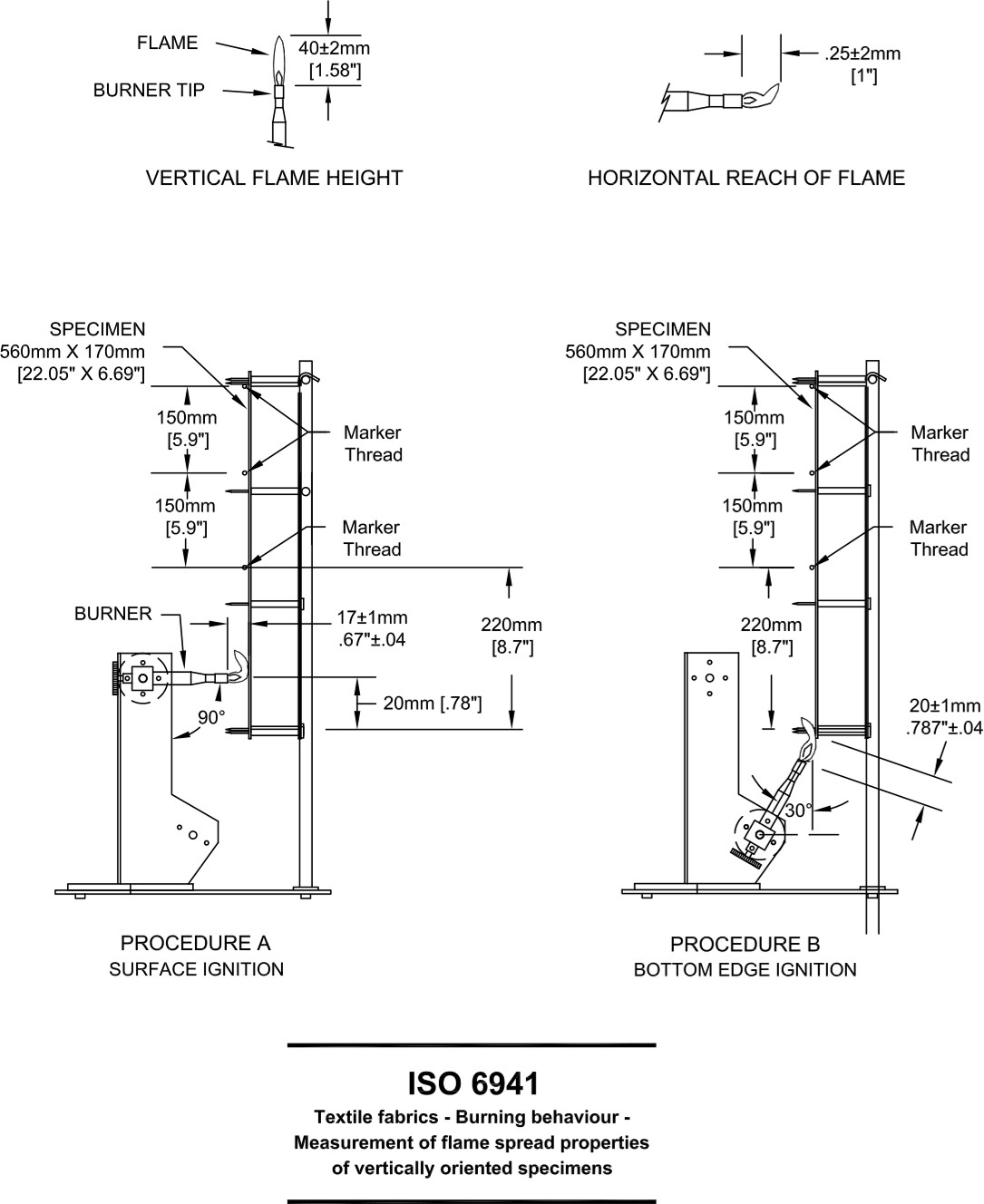

Textile Fabrics – Burning Behavior – Measurement of Flame Spread Properties of Vertically Oriented Specimens

SCOPE/PURPOSE OF TEST:

To measure the propensity of a material to either resist ignition or to display limited flame progression when subjected to a small match-type flame source.

BRIEF DESCRIPTION OF TEST:

A specimen 560 mm x 170 mm is pinned to a specimen holder in a vertical configuration. The ignition source is a micro burner that emits a 40 mm flame. The flame is applied to either the surface of the material or the edge of the material typically for a period of 10 seconds. Other ignition times might be specified.

Three sets of marker threads are strung horizontally across the width of the specimen holder at distances of 220 mm, 370 mm, and 520 mm above the bottom edge of the specimen holder.

Burner to specimen configuration is described below:

Surface Ignition: The burner is set at an angle of 90 degrees in relation to the face of the specimen. The distance between the burner tip and the specimen face is set at 17 mm.

Edge Ignition: The burner is set at an angle of 30 degrees in relation to the bottom edge of the specimen. The distance between the burner tip and the bottom edge of the specimen is set at 20 mm.

The test (either edge or surface ignition) records the time when any marker thread is severed.

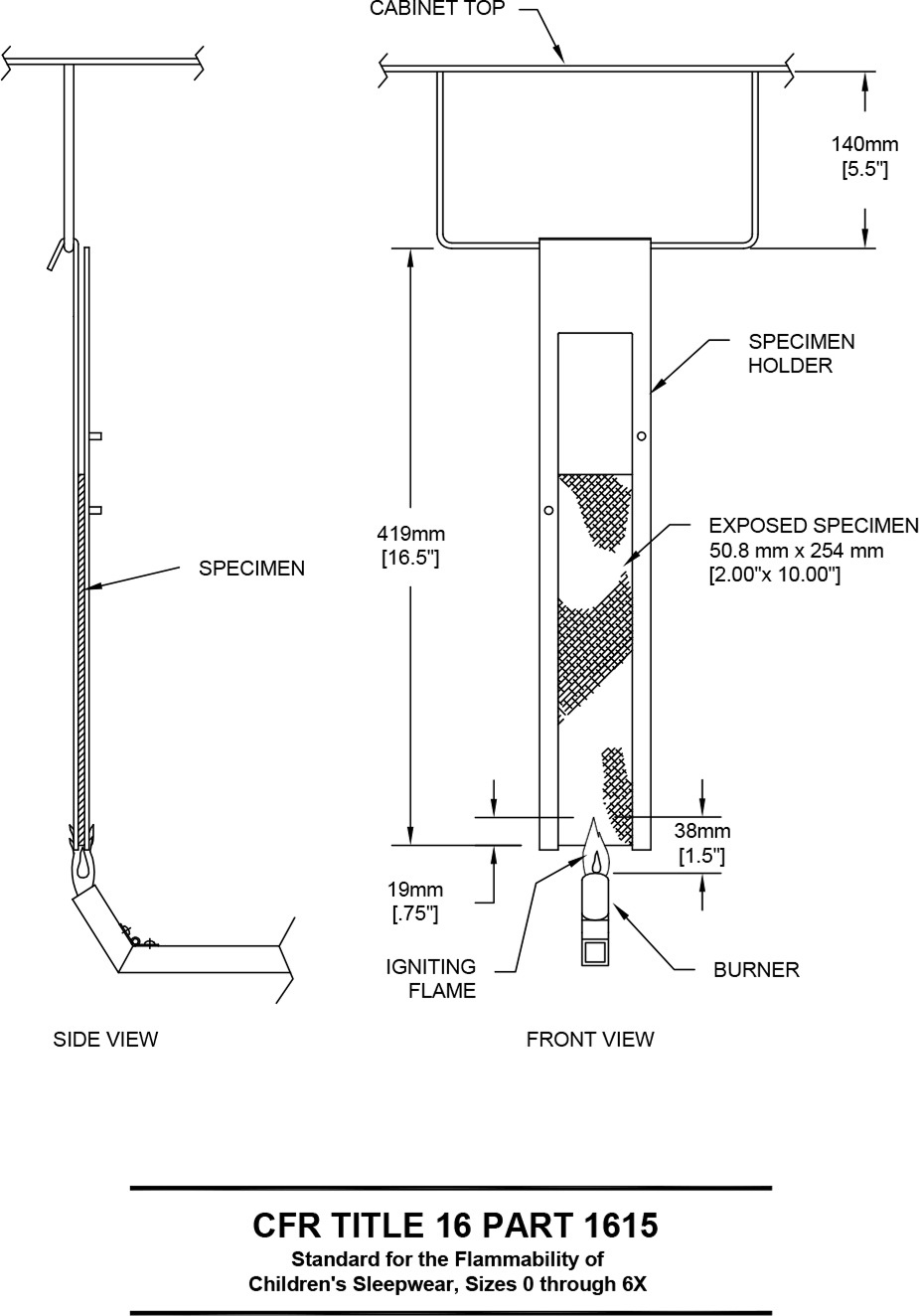

Part 1616 – Standard for the Flammability of Children’s Sleepwear Sizes 0 through 6x (FF-371)

FABRIC QUALIFICATION

SCOPE/PURPOSE OF TEST:

All fabric used in children’s sleepwear items sizes 0 through 6X.

A fabric test needs to be conducted for each fabric lot up to 5,000 yards. (See CFR 1615 for details on garment sampling.)

BRIEF DESCRIPTION OF TEST:

The material to be tested is placed inside a metal frame which covers both sides of the material. An area 2” x 10” of the material remains exposed. The framed material is placed into the test cabinet in a vertical position and suspended over a 1.5” test flame for a period of 3 seconds. The bottom edge of the test specimen hangs 0.75” into the flame. After all flaming on the specimen has ceased, the length of the degraded area is measured and reported as “char length”.

A “full specimen burn” is recorded if the char length extends the full 10” length of the test specimen.

ACCEPTANCE CRITERIA:

Number of Specimens Testing | Maximum Average Char Length Permitted* | Maximum Number of Full Specimen Burns Permitted |

|---|---|---|

10 | 7.0″ | 0 |

15 | 7.0″ | 1 |

*Per each sample (5 specimens)

NOTE: The same test is required for garment seams and trims; however, the details of the acceptance criteria differ. See CFR 1615 for full details on prototype testing and garment testing.

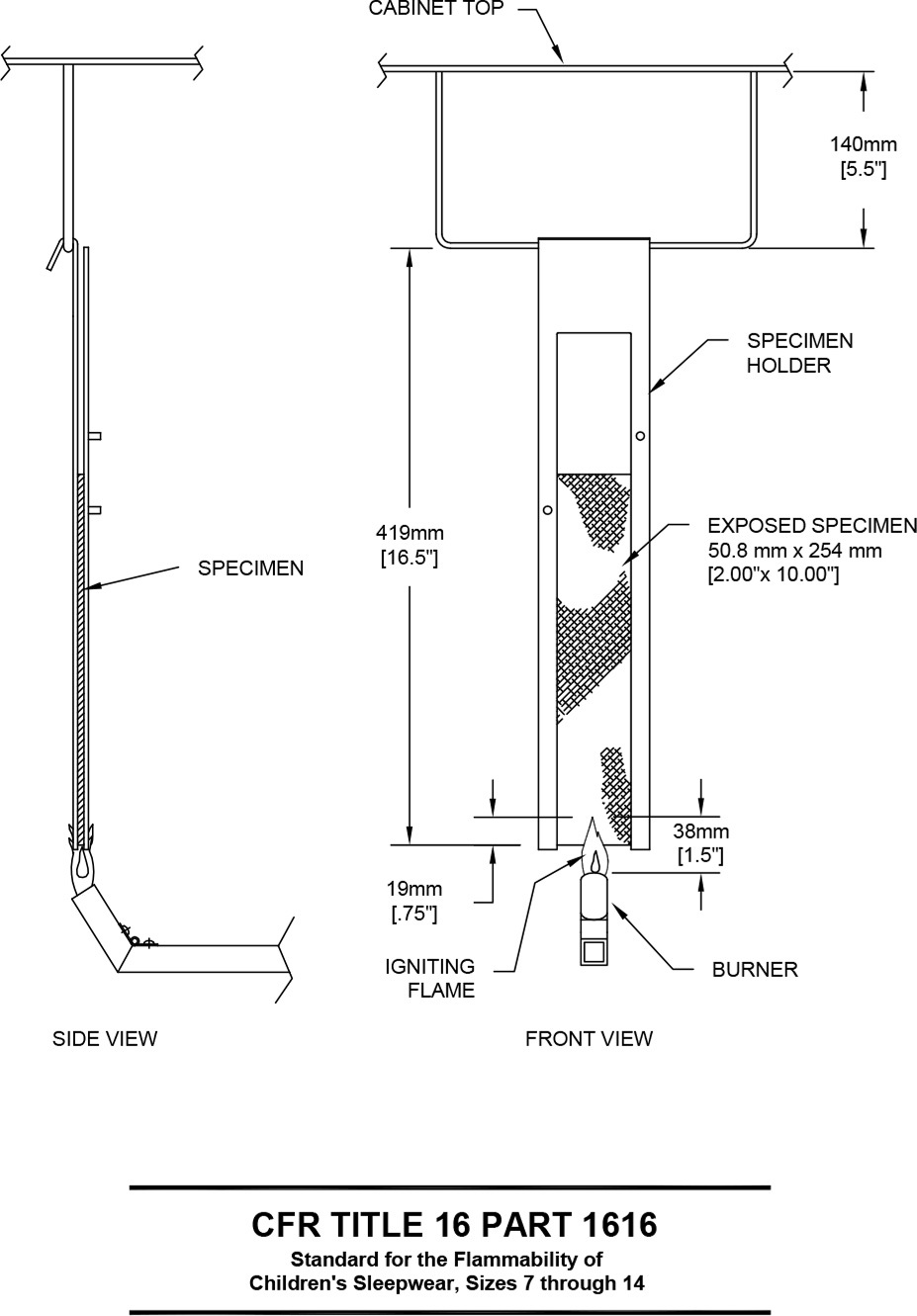

Part 1616 – Standard for the Flammability of Children’s Sleepwear Sizes 7 through 14 (FF 5-74)

FABRIC QUALIFICATION

SCOPE/PURPOSE OF TEST:

All fabric used in children’s sleepwear items sizes 7 through 14.

A fabric test needs to be conducted for each fabric lot up to 5,000 yards. (See CFR 1616 for details on garment sampling.)

BRIEF DESCRIPTION OF TEST:

The material to be tested is placed inside a metal frame which covers both sides of the material. An area 2” x 10” of the material remains exposed. The framed material is placed into the test cabinet in a vertical position and suspended over a 1.5” test flame for a period of 3 seconds. The bottom edge of the test specimen hangs 0.75” into the flame. After all flaming on the specimen has ceased, the length of the degraded area is measured and reported as “char length”.

A “full specimen burn” is recorded if the char length extends the full 10” length of the test specimen.

ACCEPTANCE CRITERIA:

Number of Specimens Testing | Maximum Average Char Length Permitted* | Maximum Number of Full Specimen Burns Permitted |

|---|---|---|

10 | 7.0″ | 0 |

15 | 7.0″ | 1 |

*Per each sample (5 specimens)

NOTE: The same test is required for garment seams and trims; however, the details of the acceptance criteria differ. See CFR 1616 for full details on prototype testing and garment testing.